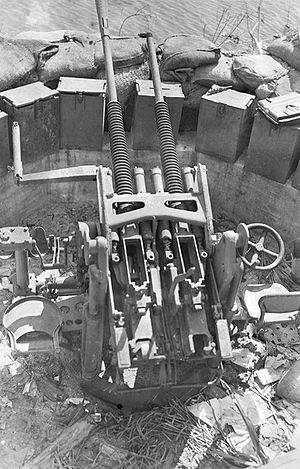

The Type 96 25mm Gun (ä¹å…å¼äºŒå五ç²é«˜è§’機銃, KyÅ«roku-shiki nijyÅ«go-miri KÅkakukijÅ«?) was an automatic cannon used by the Imperial Japanese Navy during World War II. A local built variant of the French Hotchkiss 25mm anti-aircraft gun, it was primarily used as an anti-aircraft gun in fixed mounts with between one and three guns, but was designed as a dual-purpose weapon for use against armored vehicles as well.

In 1935 the Imperial Japanese Navy decided to replace the earlier 40 mm Vickers "pom-pom" guns with a 25 mm Hotchkiss design. A party of Japanese officers and engineers traveled to France to evaluate the design in 1935 and an order was placed for a number of guns and mounts for evaluation. Firing tests of these guns were conducted at Yokosuka Naval Arsenal in 1935. The first few weapons were built in France under the designation “Type 94†and “Type 95â€, with the mass production model produced at the Yokosuka Arsenal being designated “Type 96â€.

The Japanese made a number of minor changes to the original Hotchkiss design and production process, changing some components from forgings to castings to simplify production and replacing the simple conical flash suppressor with a Rheinmetall-type design. A submarine-mountable version of the gun was also produced, which made extensive use of stainless steel.