Model or part number: A36541

About this product

Countersink in second end is 0.210 in dia times 90 deg; threads are 10-32 unf; first end is rounded 45 deg times 0.030; second end head is a hex and is rounded 30 deg

Stop-receiver Fixture Plunger NSN 3040-01-494-3956.

Factory New, New Material, New Surplus, Overhauled, Serviceable, Repairable, and AS Removed / Used material will be accompanied by a Certificate of Conformance, and any other documents/trace when applicable. We have a 7 year record retention.

We are committed to quality and follow an AS9120 quality management system. AeroBase Group is HAZMAT certified and registered with DDTC,

ITAR, and Aviation Suppliers Association (ASA). All products are 100% inspected.

Quality Commitment »

Delivery of IN-STOCK orders ship same-day when order is placed before 2:00 PM EST.

Delivery dates for NON-STOCK items are estimates based on current backlog and are subject to confirmation at the time of order.

| NSN | Component Description |

|---|---|

| NSN 5310-01-493-3519 | Blind Rivet Plain Nut |

| NSN 5935-01-493-3528 | Electrical Receptacle Connector |

| NSN 5935-01-493-3543 | Electrical Receptacle Connector |

| NSN 5985-01-493-6875 | Antenna Support Base |

| NSN 5915-01-493-7308 | Radio Frequency Interfere Filter |

| NSN 5310-01-493-7441 | Blind Rivet Plain Nut |

| NSN 5310-01-493-7443 | Blind Rivet Plain Nut |

| NSN 5999-01-493-7639 | Electrical Cap |

| NSN 6150-01-493-7669 | E Special Purpose Cable Assembly |

| NSN 5310-01-493-7672 | Flat Washer |

| NSN 6150-01-493-7673 | Electrical Power Cable Assembly |

| NSN 6150-01-493-7677 | E Special Purpose Cable Assembly |

| NSN 5310-01-493-7679 | Sleeve Nut |

| NSN 6150-01-493-7683 | E Special Purpose Cable Assembly |

| NSN 5310-01-493-7690 | Shouldered Washer |

| NSN 5995-01-493-7693 | Radio Frequency Cable Assembly |

| NSN 5310-01-493-7694 | Shouldered Washer |

| NSN 5330-01-493-7914 | Rubber Strip |

| NSN 5330-01-493-7915 | Gasket |

| NSN 5330-01-493-7921 | Gasket |

| NSN 6625-01-493-8113 | Voltmeter |

| NSN 5930-01-493-8114 | Pressure Switch |

| NSN 5999-01-493-8118 | Radio Frequency/electromag Panel |

| NSN 5925-01-493-8123 | Circuit Breaker |

| NSN 5995-01-493-8210 | Radio Frequency Cable Assembly |

| NSN 5995-01-493-8219 | Radio Frequency Cable Assembly |

| NSN 5995-01-493-8220 | Radio Frequency Cable Assembly |

| NSN 5995-01-493-8225 | Radio Frequency Cable Assembly |

| NSN 5995-01-493-8230 | Radio Frequency Cable Assembly |

| NSN 5995-01-493-8233 | Radio Frequency Cable Assembly |

| NSN 5940-01-493-8538 | Terminal Board Assembly |

| NSN 5940-01-493-8575 | Grounding Terminal Strip |

| NSN 6020-01-493-8719 | Fiber Optic Cable Assembly |

| NSN 6020-01-493-8722 | Fiber Optic Cable Assembly |

| NSN 5340-01-493-8961 | Support Hook |

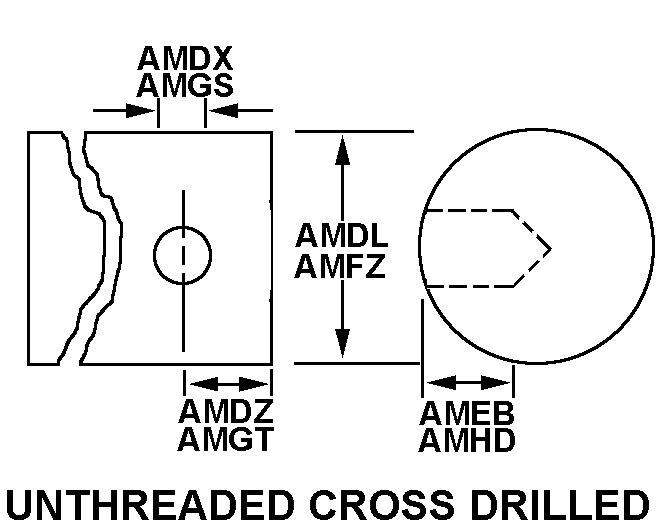

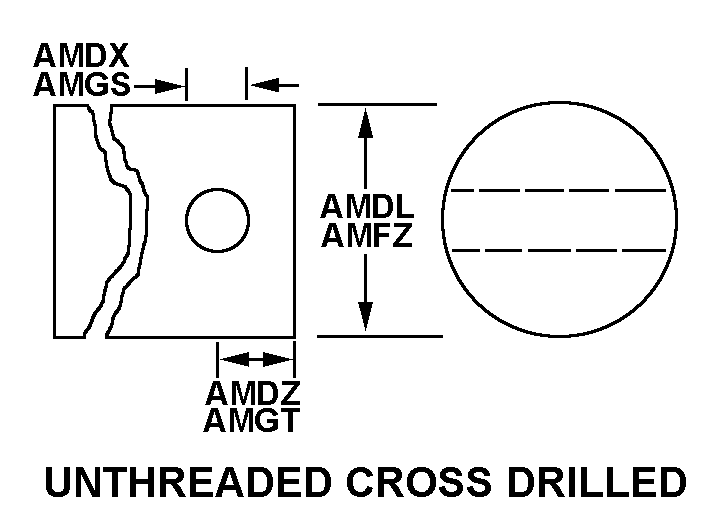

A shaft having two or more different diameters (greater than 0.031 inches (0.79 millimeter)) along its length. It must have one or more of the following conditions: a specified surface finish designation in the range 1 to 125 microinches (0.025 to 3.2 micrometers) arithmetical average (aa), machined peripheral flat(s), circular groove(s), keyway(s), splines, threads, or holes. The ends and/or shoulders may be machined to accommodate bearings, couplings, and the like. It is not designed for use in aligning by fitting into corresponding holes of another item. For items used to support rotating members see axle(1), shouldered. For items not having any of the above conditions see pin, shoulder, headless. Excludes shaft(1), straight; and axle(1), straight.

Packing shall be accomplished in accordance with table c.Ii for the packing level specified. closure, sealing and reinforcement shall be in accordance with applicable specification for shipping container.

Packing shall be accomplished in accordance with table c.Ii for the packing level specified. closure, sealing and reinforcement shall be in accordance with the appropriate shipping container specification.

Options can be exercised as to specific method of preservation or dod approved packaging materials to be used. however, basic preservation method shall be retained, supplemental data shall be complied with, and unit package dimensions shall not be increased by more than one inch. equal or better protection shall be given the item and there shall be no increase in the package cost.

No special marking.

Physical protection.

No requirement.

No requirement.

Transmission Shafts and Cranks, Except Camshafts and Crankshafts

Industrial Machines, Other

Transmission Shafts (including Cam and Crank Shafts) and Cranks

No special type of cargo code applicable.

Motors and parts, (machinery and parts),(less than 35 feet).

Trailers, vehicles, machinery, shop and warehouse equipment and supplies including special tools and equipment, ground servicing.

Shipment is not a consolidation and does not exceed 84 inches in any dimension.

Other or no special handling required (sh)

| Code | Definition |

|---|---|

| FN | Factory New. Parts manufactured by the OEM and includes manufacturer certification. |

| NE | New. Parts manufactured by the OEM. May include manufacturer certification or company certification. |

| NS | New Surplus. New material item purchased from excess inventory. |

| OH | Overhauled. Product has been rebuilt and tested in accordance with the manufacturer's specifications by a repair shop (MRO). |

| SV | Serviceable product. |

| AR | As Removed. Product removed from aircraft or platform with no guarentee on the functionality of the part. |

| RP | Repairable. Product can be repaired by a MRO and be given a FAA 8130 or EASA Form 1 certification. |

| Part Number | RNVC | RNAAC | DAC | CAGE |

|---|---|---|---|---|

| A36541 | 2 | ZZ | 5 | 62809 |

| 17-1-6734 | 2 | ZZ | A | 81337 |

| A36541 | 9 | ZZ | A | 41625 |

| Name | No. Items | |||

|---|---|---|---|---|

| [You must be logged in to use lists] | ||||