Model or part number: SR62D

Twist Drill Bit NSN 5133-01-195-1957.

Factory New, New Material, New Surplus, Overhauled, Serviceable, Repairable, and AS Removed / Used material will be accompanied by a Certificate of Conformance, and any other documents/trace when applicable. We have a 7 year record retention.

We are committed to quality and follow an AS9120 quality management system. AeroBase Group is HAZMAT certified and registered with DDTC,

ITAR, and Aviation Suppliers Association (ASA). All products are 100% inspected.

Quality Commitment »

Delivery of IN-STOCK orders ship same-day when order is placed before 2:00 PM EST.

Delivery dates for NON-STOCK items are estimates based on current backlog and are subject to confirmation at the time of order.

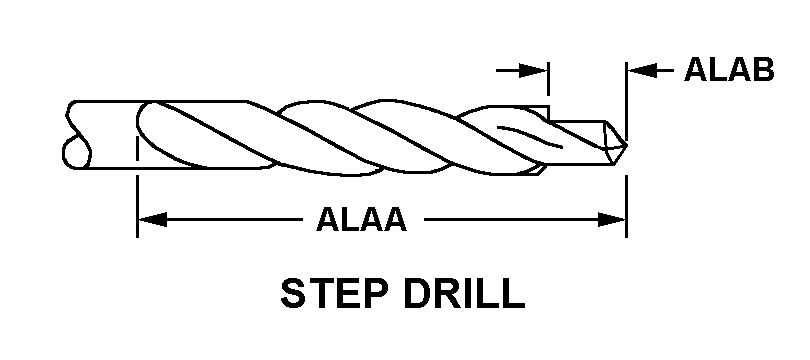

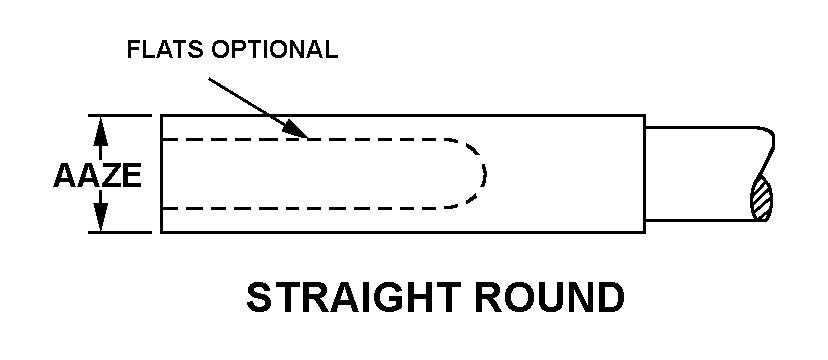

An end cutting tool having two or more cutting edges, and having helical flutes or grooves adjacent thereto for the admission of coolant and the ejection of cuttings or chips. It is used for drilling holes in various materials. Excludes drill, masonry (as modified); and drill,twist, bone. See also drill, pivot, jeweler's and drill, hardened steel, carbide tipped.

Drilling, Threading Or Tapping Tools and Parts Thereof, Base Metal

Photo, Service Industry Machinery

Drilling, Threading and Tapping Tools

No special type of cargo code applicable.

Engineer and material handling equipment, test/tool sets and equipment.

Construction materials: includes paint and related materials, prefabricated building, wood products, metal and composition mater.

Shipment is not a consolidation and does not exceed 84 inches in any dimension.

Other or no special handling required (sh)

| Code | Definition |

|---|---|

| FN | Factory New. Parts manufactured by the OEM and includes manufacturer certification. |

| NE | New. Parts manufactured by the OEM. May include manufacturer certification or company certification. |

| NS | New Surplus. New material item purchased from excess inventory. |

| OH | Overhauled. Product has been rebuilt and tested in accordance with the manufacturer's specifications by a repair shop (MRO). |

| SV | Serviceable product. |

| AR | As Removed. Product removed from aircraft or platform with no guarentee on the functionality of the part. |

| RP | Repairable. Product can be repaired by a MRO and be given a FAA 8130 or EASA Form 1 certification. |

| Part Number | RNVC | RNAAC | DAC | CAGE |

|---|---|---|---|---|

| SR62D | 2 | 75 | 4 | 83324 |

| Name | No. Items | |||

|---|---|---|---|---|

| [You must be logged in to use lists] | ||||