Model or part number: CA28106-06-7PK

Captive Screw NSN 5305-01-372-3021.

Factory New, New Material, New Surplus, Overhauled, Serviceable, Repairable, and AS Removed / Used material will be accompanied by a Certificate of Conformance, and any other documents/trace when applicable. We have a 7 year record retention.

We are committed to quality and follow an AS9120 quality management system. AeroBase Group is HAZMAT certified and registered with DDTC,

ITAR, and Aviation Suppliers Association (ASA). All products are 100% inspected.

Quality Commitment »

Delivery of IN-STOCK orders ship same-day when order is placed before 2:00 PM EST.

Delivery dates for NON-STOCK items are estimates based on current backlog and are subject to confirmation at the time of order.

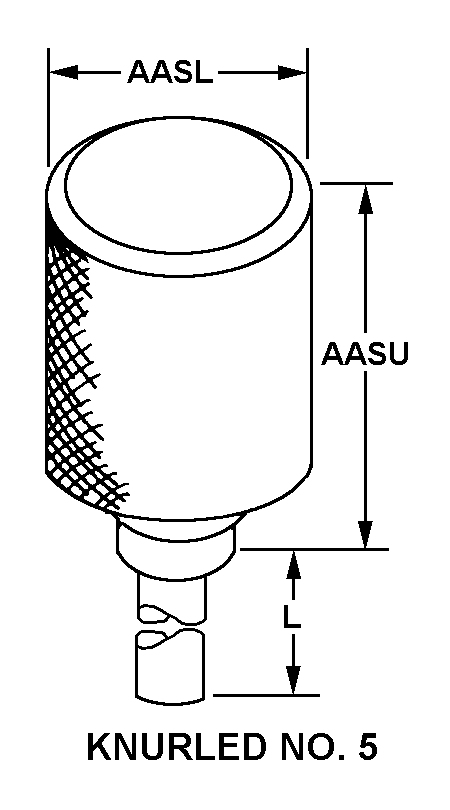

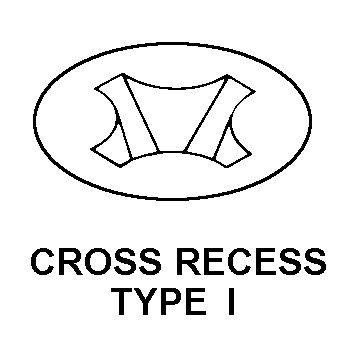

A headed, threaded fastening device over which may be assembled; (1) a stand-off; (2) a flanged bushing with washer(s) and/or a shouldered bushing without a flange, or it may have an internally threaded sleeve that is an integral part of the screw; a washer and an externally thread self-locking bushing that is driven by an inserted driver. Attached to panel by threaded bushing or by flaring end of stand-off, or bushing. Used in conjunction with a speed nut, nut plate, or driven into a threaded hole in the item that the panel is fastened to. May be spring loaded.

Packing shall be accomplished to meet the performance test requirements of astm-d4169, distribution cycle 18, assurance level 1.

Packing shall be accomplished in accordance with table c.Ii for the packing level specified. closure, sealing and reinforcement shall be in accordance with the appropriate shipping container specification.

Options can be exercised as to specific method of preservation or dod approved packaging materials to be used. however, basic preservation method shall be retained, supplemental data shall be complied with, and unit package dimensions shall not be increased by more than one inch. equal or better protection shall be given the item and there shall be no increase in the package cost.

No special marking.

Physical protection.

No requirement.

No requirement.

No special type of cargo code applicable.

Metal hardware.

Construction materials: includes paint and related materials, prefabricated building, wood products, metal and composition mater.

Shipment is not a consolidation and does not exceed 84 inches in any dimension.

Other or no special handling required (sh)

| Code | Definition |

|---|---|

| FN | Factory New. Parts manufactured by the OEM and includes manufacturer certification. |

| NE | New. Parts manufactured by the OEM. May include manufacturer certification or company certification. |

| NS | New Surplus. New material item purchased from excess inventory. |

| OH | Overhauled. Product has been rebuilt and tested in accordance with the manufacturer's specifications by a repair shop (MRO). |

| SV | Serviceable product. |

| AR | As Removed. Product removed from aircraft or platform with no guarentee on the functionality of the part. |

| RP | Repairable. Product can be repaired by a MRO and be given a FAA 8130 or EASA Form 1 certification. |

| Part Number | RNVC | RNAAC | DAC | CAGE |

|---|---|---|---|---|

| CA28106-06-7PK | 2 | KZ | A | 29372 |

| Name | No. Items | |||

|---|---|---|---|---|

| [You must be logged in to use lists] | ||||