Model or part number: BACB30US5K14H

About this product

Requested name-tension bolt

Coaxial Connector NSN 5306-01-445-3712.

Factory New, New Material, New Surplus, Overhauled, Serviceable, Repairable, and AS Removed / Used material will be accompanied by a Certificate of Conformance, and any other documents/trace when applicable. We have a 7 year record retention.

We are committed to quality and follow an AS9120 quality management system. AeroBase Group is HAZMAT certified and registered with DDTC,

ITAR, and Aviation Suppliers Association (ASA). All products are 100% inspected.

Quality Commitment »

Delivery of IN-STOCK orders ship same-day when order is placed before 2:00 PM EST.

Delivery dates for NON-STOCK items are estimates based on current backlog and are subject to confirmation at the time of order.

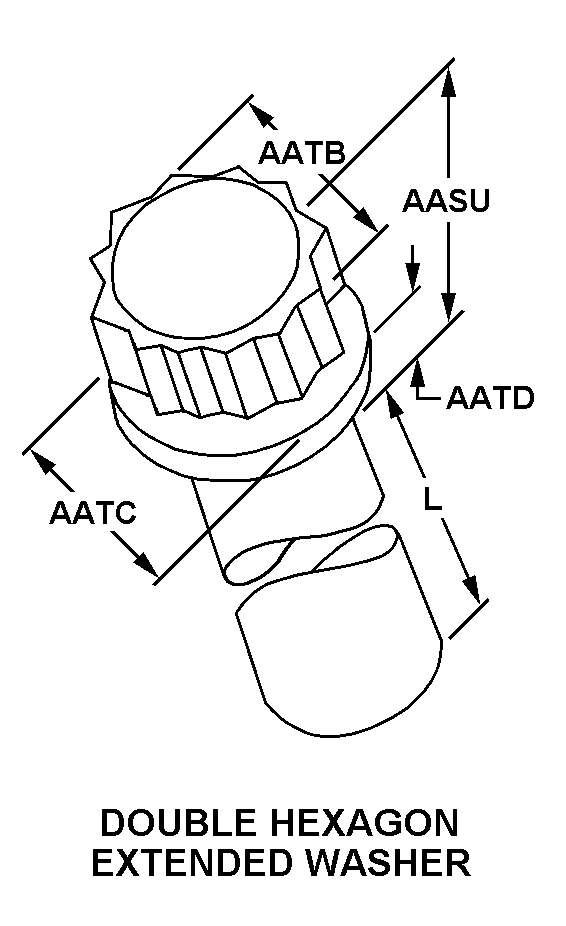

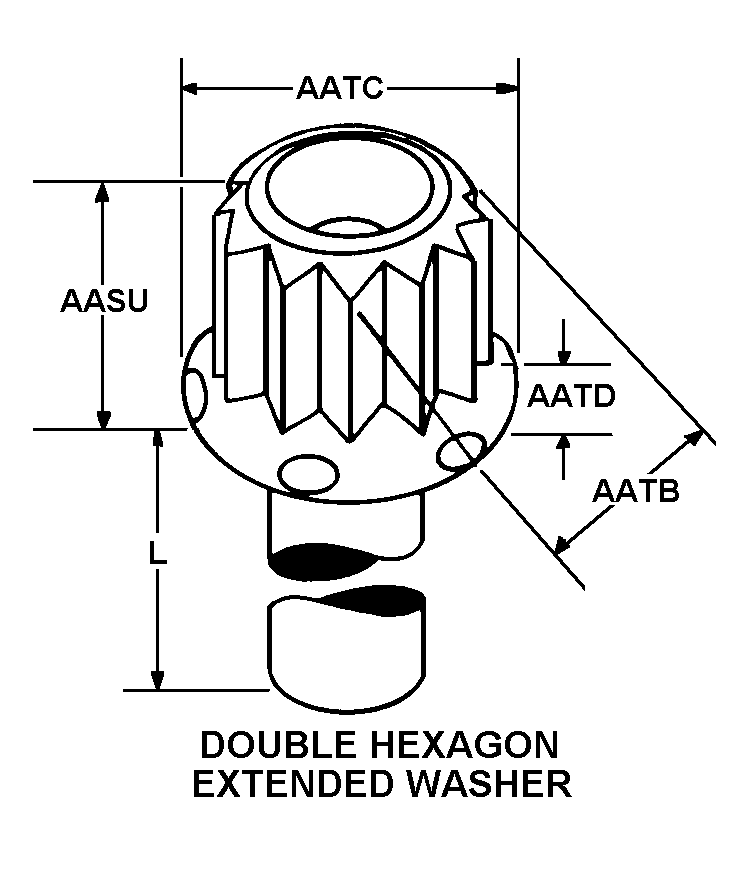

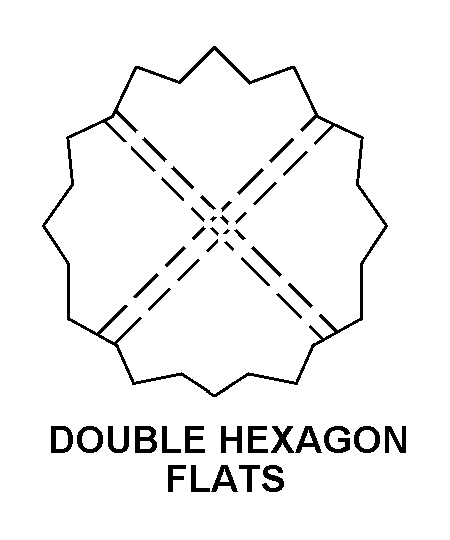

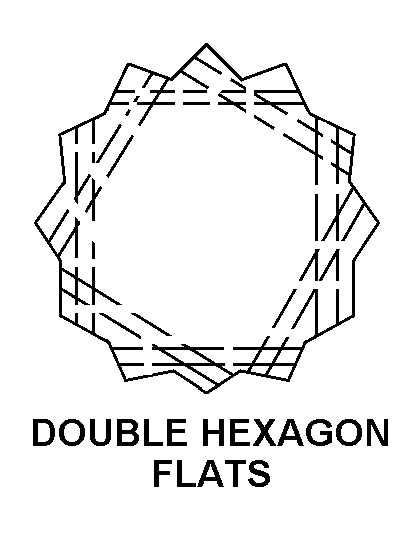

A high strength, 160,000 pounds per square inch (1100 megapascals) minimum tensile strength externally threaded fastener designed for use in applications involving great shear stress. The head is designed to accommodate an external wrench or driver. The head is not designed to be held or driven with an inserted driver, nor is it designed for rotation by the thumb and fingers. The unthreaded portion is of specific grip length, plated or unplated, and is machined to a tolerance of one thousandth (0.001) of an inch (0.025 mm) or less of a specific diameter for items one inch (25 mm) or less in diameter. Items over one inch (25 mm) in diameter shall have a tolerance of fifteen ten thousandths (0.0015) of an inch (0.038 mm) or less. The nominal major diameter of the threads shall be at least one thousandth (0.001) of an inch (0.025 mm) below the minimum shank diameter, but not below the minimum major diameter for applicable class of fit, as shown in the screw thread standards, fed std h28 and/or other nationally recognized standards. A locking feature may be incorporated in the design of the head or threads. See bolt, machine and bolt, clevis.

Packing shall be accomplished to meet the performance test requirements of astm-d4169, distribution cycle 18, assurance level 1.

Packing shall be accomplished in accordance with table c.Ii for the packing level specified. closure, sealing and reinforcement shall be in accordance with the appropriate shipping container specification.

Options can be exercised as to specific method of preservation or dod approved packaging materials to be used. however, basic preservation method shall be retained, supplemental data shall be complied with, and unit package dimensions shall not be increased by more than one inch. equal or better protection shall be given the item and there shall be no increase in the package cost.

No special marking.

Physical protection.

No requirement.

No requirement.

Other Articles Of Nickel, Nesoi (excluding Cloth, Grill & Netting Of Nickel Wire)

Finished Metal Shapes

Articles Of Nickel, N.e.s.

No special type of cargo code applicable.

Bolts or nuts (iron or steel),(less than 35 feet).

Supplies and equipment for aircraft and aerial targets, including aircraft and maintenance parts, aircraft accessories, aircraft.

Shipment is not a consolidation and does not exceed 84 inches in any dimension.

Other or no special handling required (sh)

| Code | Definition |

|---|---|

| FN | Factory New. Parts manufactured by the OEM and includes manufacturer certification. |

| NE | New. Parts manufactured by the OEM. May include manufacturer certification or company certification. |

| NS | New Surplus. New material item purchased from excess inventory. |

| OH | Overhauled. Product has been rebuilt and tested in accordance with the manufacturer's specifications by a repair shop (MRO). |

| SV | Serviceable product. |

| AR | As Removed. Product removed from aircraft or platform with no guarentee on the functionality of the part. |

| RP | Repairable. Product can be repaired by a MRO and be given a FAA 8130 or EASA Form 1 certification. |

| Part Number | RNVC | RNAAC | DAC | CAGE |

|---|---|---|---|---|

| BACB30US5K14H | 2 | ZZ | 5 | 17446 |

| BACB30US5K14H | 2 | ZZ | 2 | 06710 |

| BACB30US5K14H | 2 | ZZ | 2 | 06725 |

| BACB30US5K14H | 2 | ZZ | 2 | 17943 |

| BACB30US5K14H | 2 | ZZ | 2 | 27624 |

| BACB30US5K14H | 2 | ZZ | 2 | 56878 |

| BACB30US5K14H | 2 | ZZ | 2 | 57928 |

| BACB30US5K14H | 2 | ZZ | 2 | 92215 |

| BACB30US5K14H | 2 | ZZ | 2 | 81205 |

| BACB30US5K14H | 2 | ZZ | 5 | 5M902 |

| LE111-0067A3514 | 2 | ZZ | 2 | 43999 |

| BACB30US5K14H | 9 | ZZ | 2 | 97928 |

| Name | No. Items | |||

|---|---|---|---|---|

| [You must be logged in to use lists] | ||||