Model or part number: 12366465-1

Divergent Flap Slider NSN 5365-01-485-4602.

Factory New, New Material, New Surplus, Overhauled, Serviceable, Repairable, and AS Removed / Used material will be accompanied by a Certificate of Conformance, and any other documents/trace when applicable. We have a 7 year record retention.

We are committed to quality and follow an AS9120 quality management system. AeroBase Group is HAZMAT certified and registered with DDTC,

ITAR, and Aviation Suppliers Association (ASA). All products are 100% inspected.

Quality Commitment »

Delivery of IN-STOCK orders ship same-day when order is placed before 2:00 PM EST.

Delivery dates for NON-STOCK items are estimates based on current backlog and are subject to confirmation at the time of order.

| NSN | Component Description |

|---|---|

| NSN 2530-01-188-3117 | Vehicular Components Boot |

| NSN 4730-01-355-7652 | Quick Disconnect Coupling Half |

| NSN 2510-01-410-8075 | Metal Grille |

| NSN 3040-01-410-8104 | Shouldered Shaft |

| NSN 4730-01-410-8105 | Pipe Flange |

| NSN 3040-01-410-8107 | Bell Crank |

| NSN 4730-01-410-8108 | Pipe Nipple |

| NSN 3040-01-410-8111 | Line Actuating Cylinder Assembly |

| NSN 3040-01-410-8113 | Shouldered Shaft |

| NSN 4520-01-410-8114 | Air Conditioning-heating Reducer |

| NSN 4730-01-410-8811 | Flange To Tube Straight Adapter |

| NSN 3040-01-410-9970 | Linear Actuating Cylinder Piston |

| NSN 3040-01-411-0672 | Rigid Connecting Link |

| NSN 3040-01-411-0673 | Rigid Connecting Link |

| NSN 3040-01-411-0675 | Rigid Connecting Link |

| NSN 3040-01-411-2140 | Housing Adapter |

| NSN 3040-01-411-2143 | Rigid Connecting Link |

| NSN 2910-01-411-2748 | Engine Fuel Tank |

| NSN 2540-01-411-3953 | Vehicular Seat Support |

| NSN 2940-01-411-3962 | Intake Air Cleaner |

| NSN 4730-01-411-3970 | Pipe Tee |

| NSN 4710-01-411-4188 | Metal Tube Assembly |

| NSN 2590-01-411-4857 | Vehicular Components Bracket |

| NSN 2530-01-411-4860 | Vehicular Wheel Hub |

| NSN 2540-01-411-4861 | Vehicular Seat Support |

| NSN 4520-01-411-4862 | Flue Damper |

| NSN 2540-01-411-4863 | Vehicular Bumper |

| NSN 2910-01-411-4864 | Engine Fuel Tank |

| NSN 2910-01-411-4865 | Engine Fuel Tank |

| NSN 2510-01-411-4866 | Direct Action Shock Absorber |

| NSN 4720-01-411-4867 | Nonmetallic Hose Assembly |

| NSN 2540-01-411-4868 | Vehicular Seat |

| NSN 2540-01-411-4871 | Vehicular Seat Frame |

| NSN 2510-01-411-5298 | Air Control Guard |

| NSN 2530-01-411-6238 | Hub And Arm Assembly |

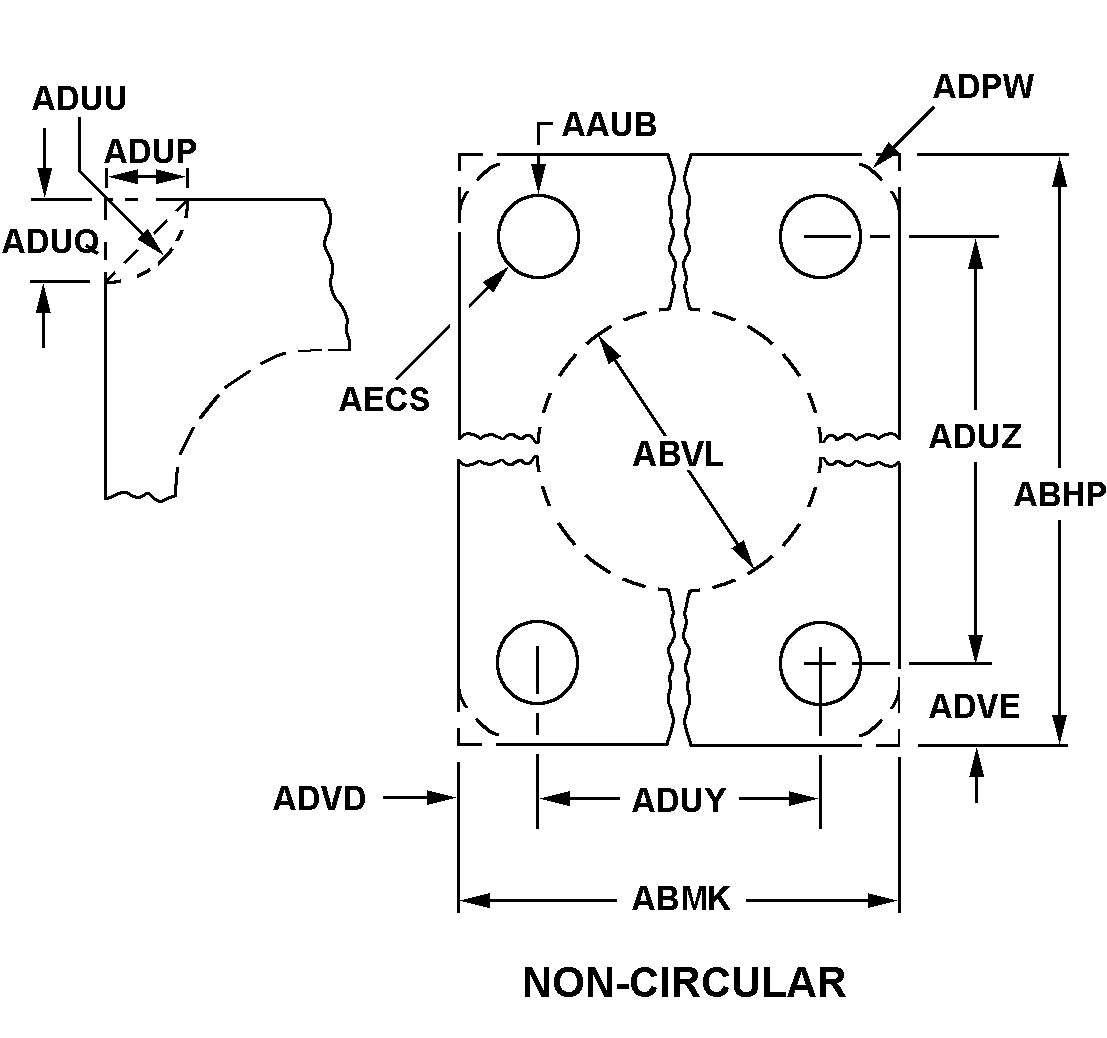

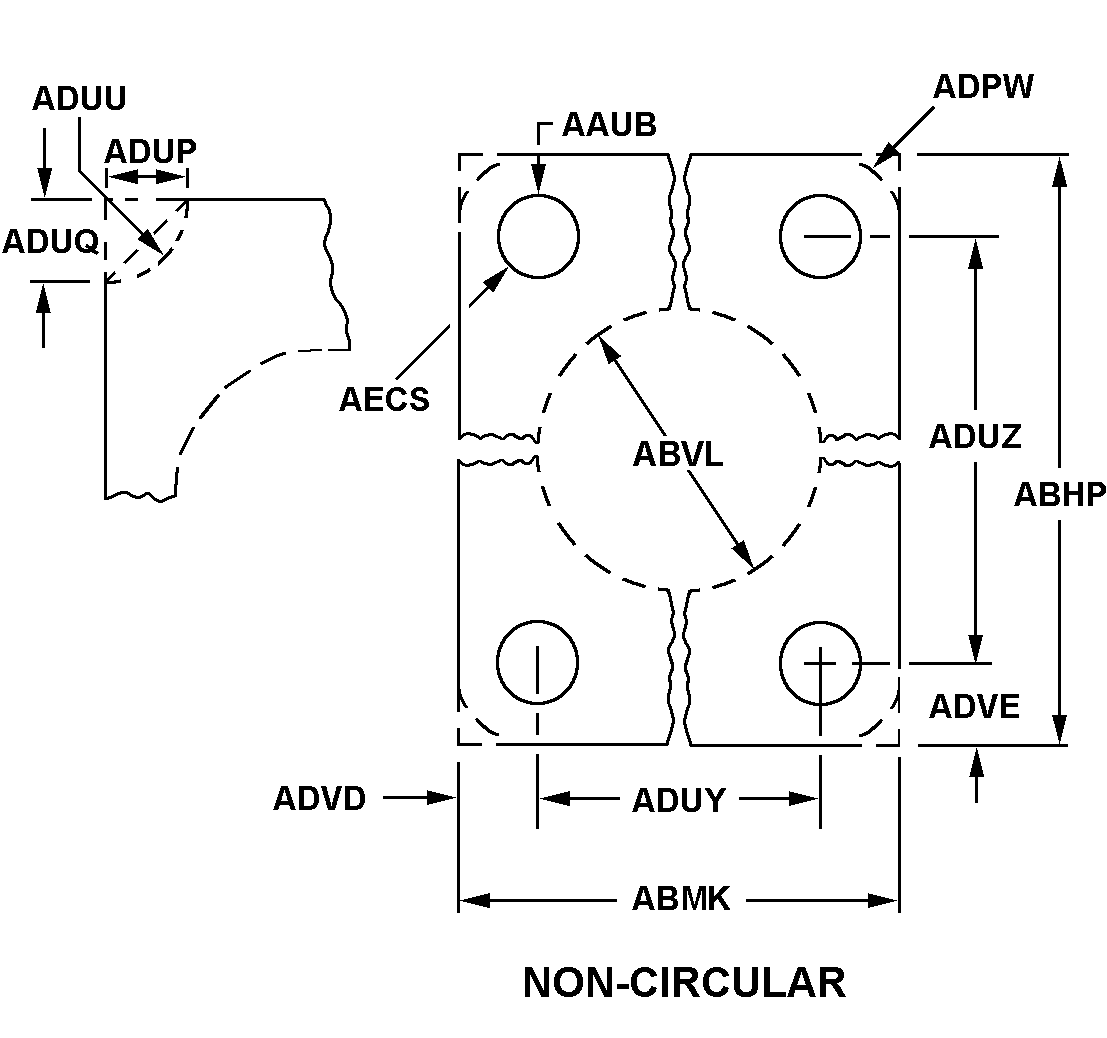

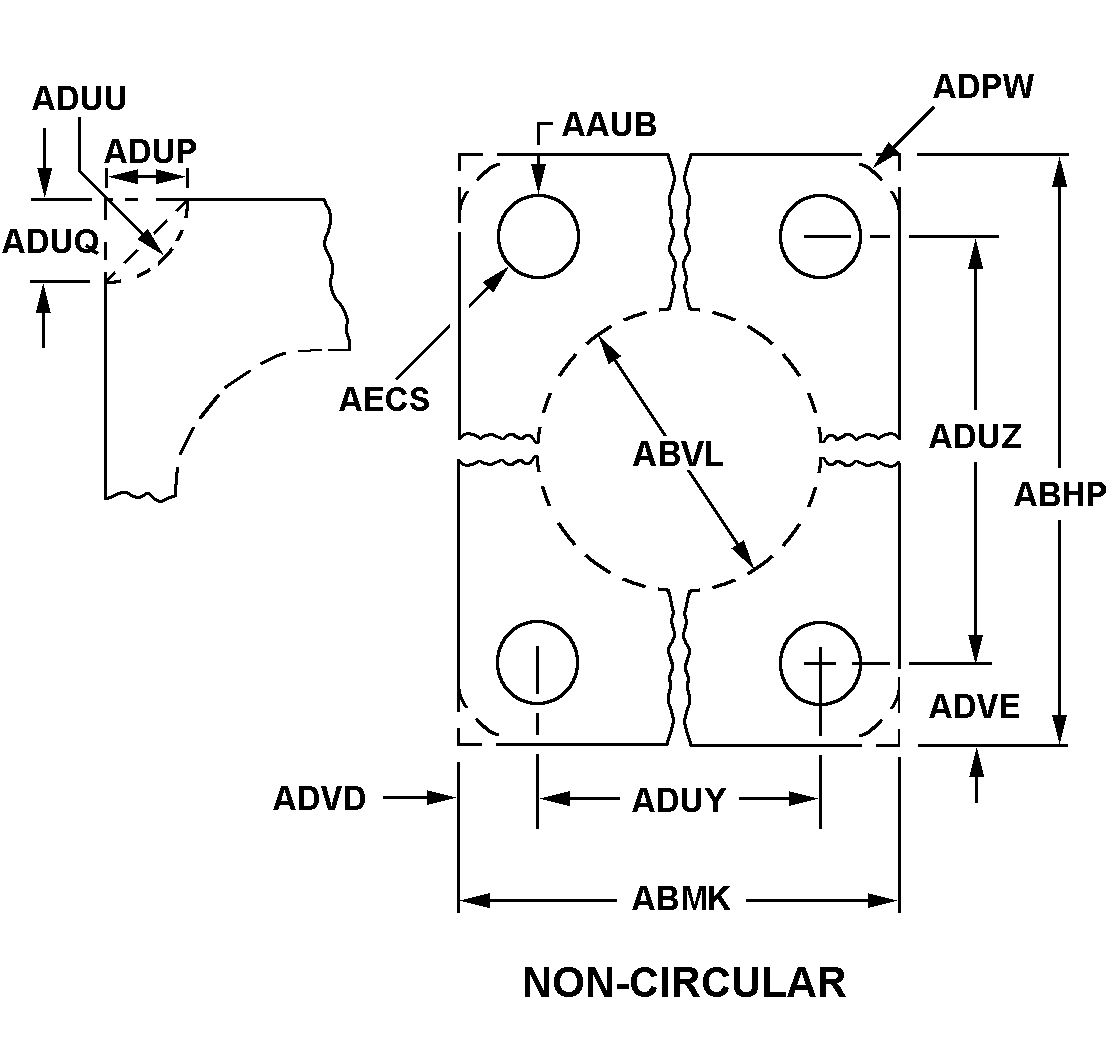

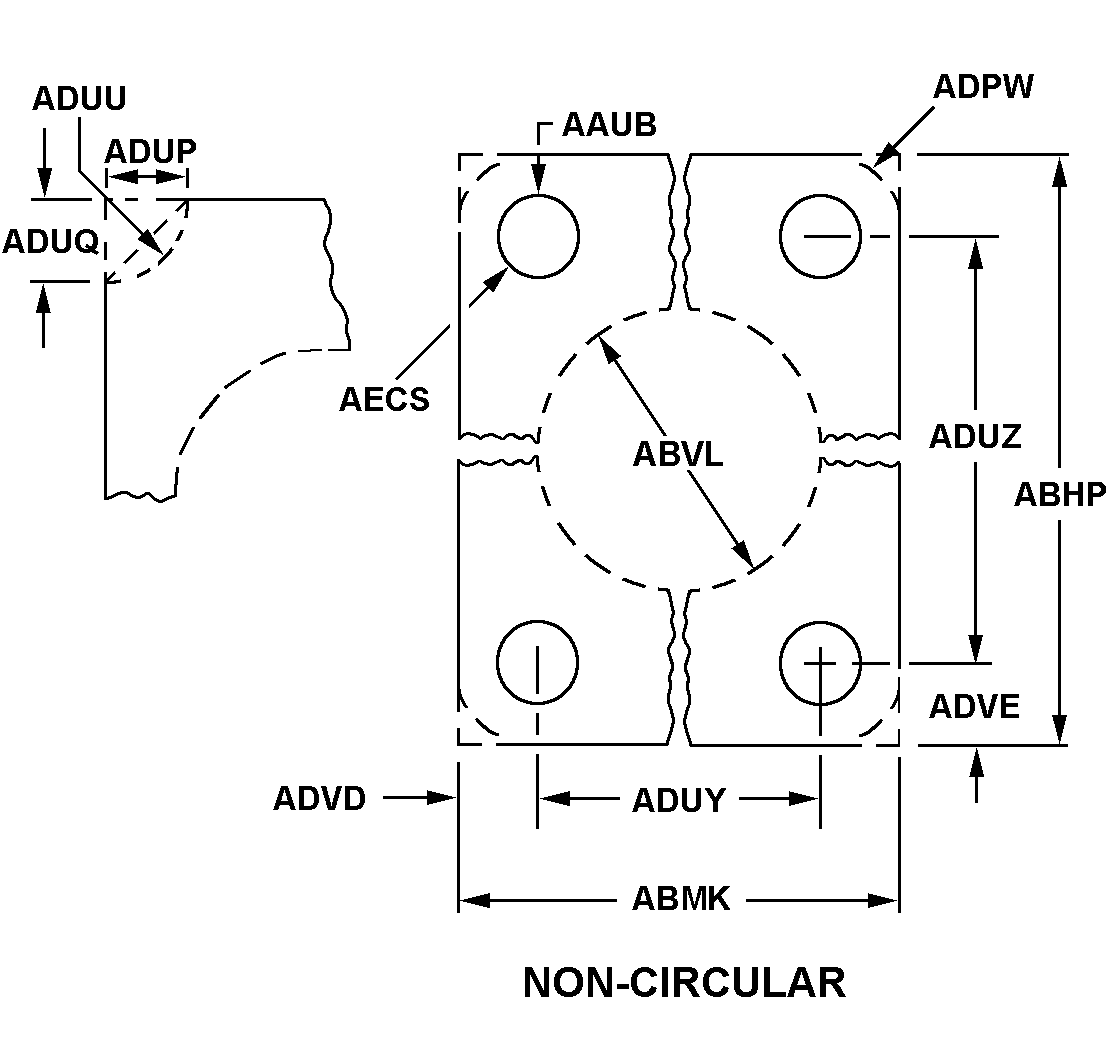

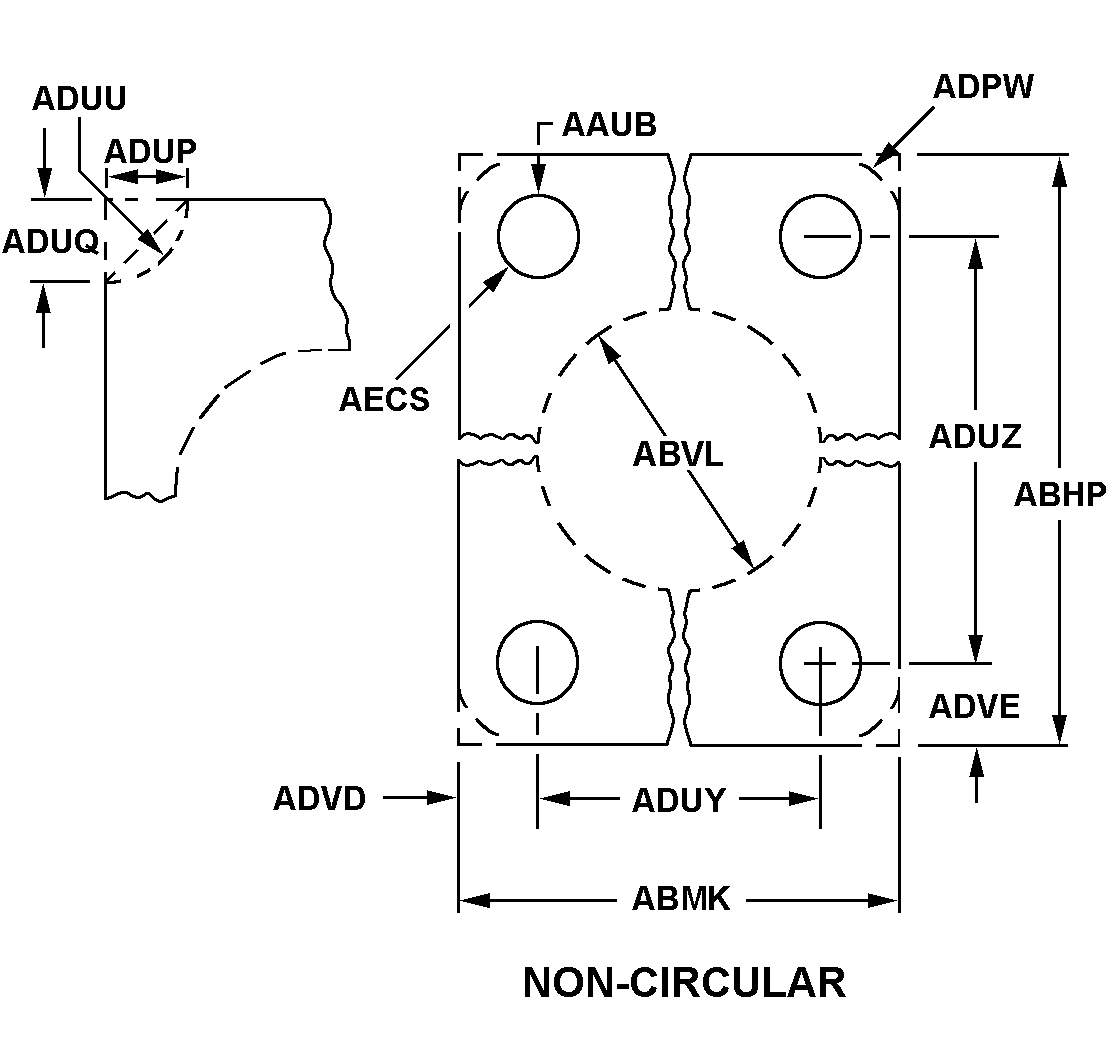

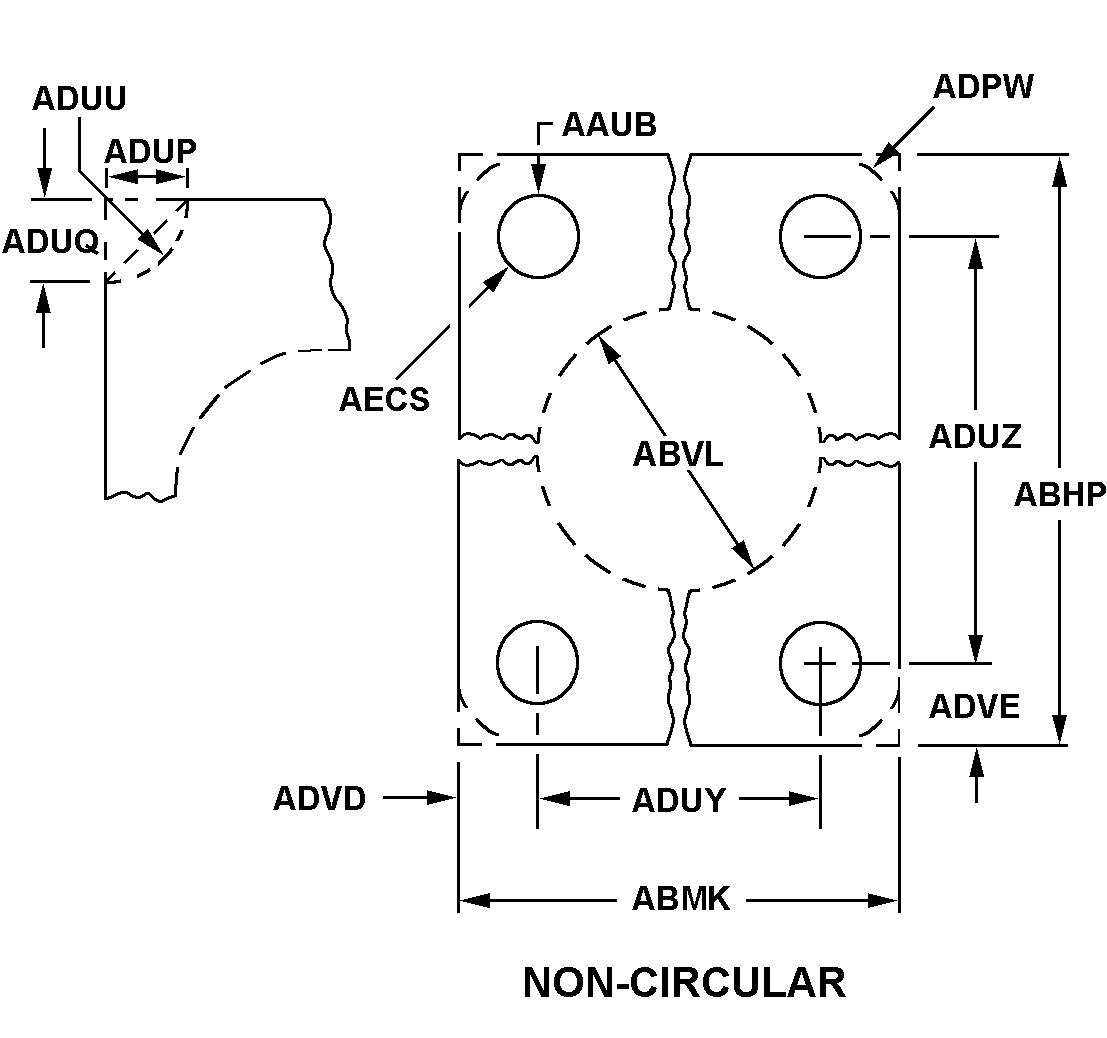

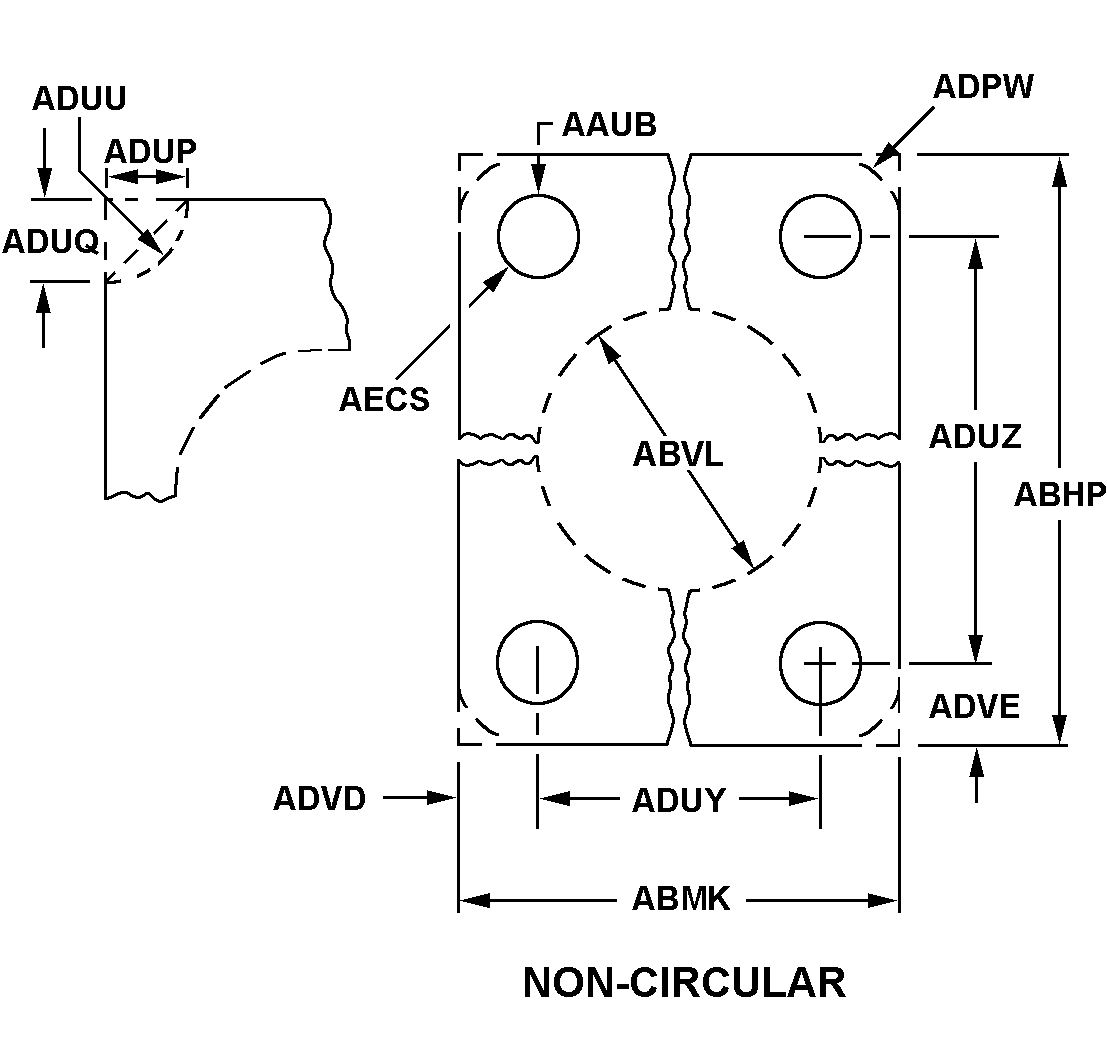

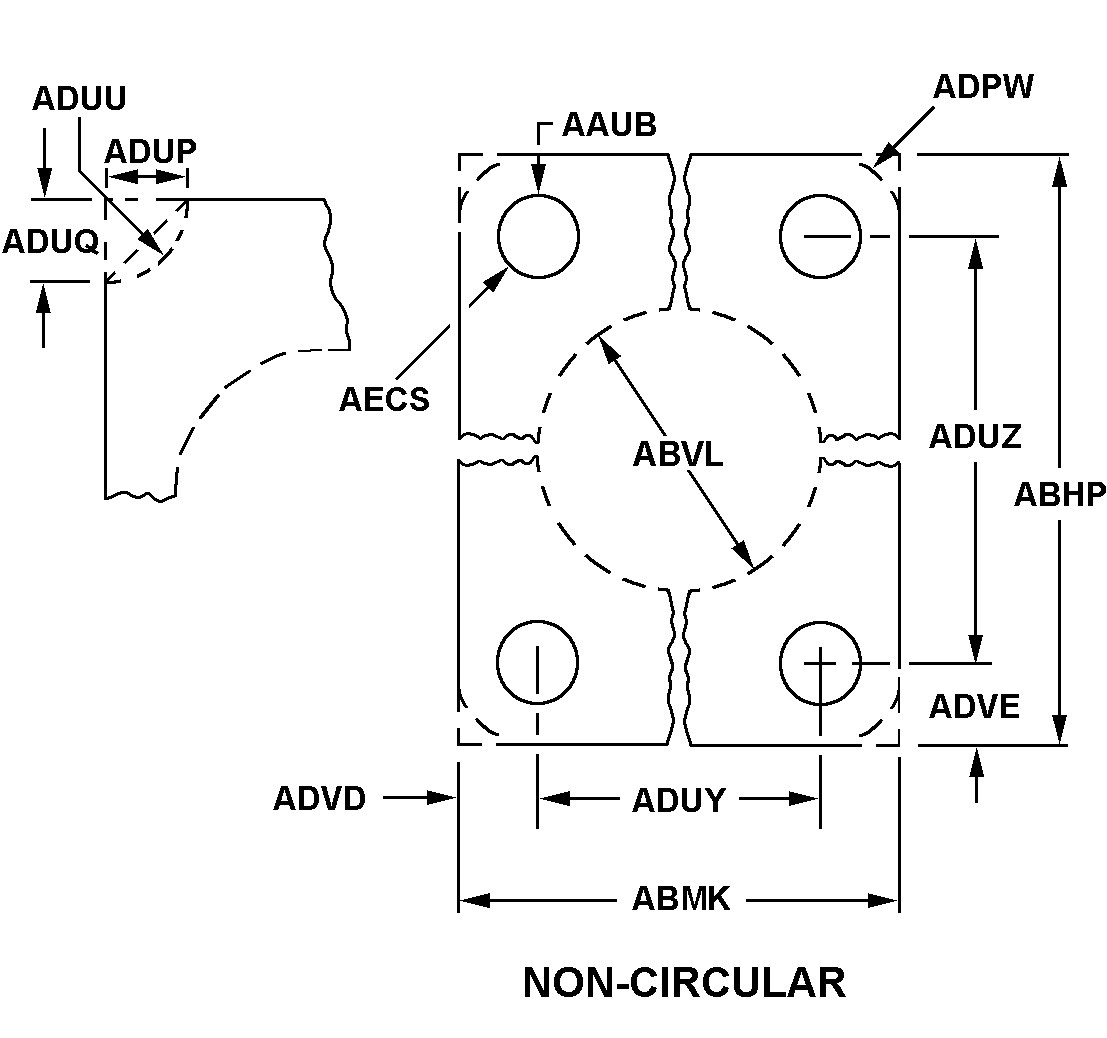

A flat metal or plastic item of various peripheral shapes having a solid (not laminated) cross-section. It is designed to maintain a predetermined distance between two surfaces. For round items without a hole having a solid rectangular cross-section use disk, solid, plain. For round or hexagonal items with only one hole centrally located and with the length (thickness) exceeding 25 percent of the outside diameter or distance across peripheral flats, see spacer, sleeve. The thickness between the two parallel bearing surfaces must be 0.006 inch, (0.152 mm) or more for items less than 1/4 inch (6.35 mm) across the peripheral diameter, or smallest overall outside dimension, or must be 0.016 inch (0.406 mm) or more for items 1/4 inch (6.35 mm) or greater across the peripheral diameter or smallest overall outside dimension. For items with a thickness less than those indicated above, see shim. For items with one hole centrally located conforming to the above dimensional criteria use washer, flat or spacer, ring as applicable. When thickness and/or outside diameter or smallest overall outside dimension is designated as a tolerance/dimension the maximum dimension will be used to determine compliance. Excludes gasket; insulator (as modified) and mounting pad, electrical-electronic component.

Packing shall be accomplished to meet the performance test requirements of astm-d4169, distribution cycle 18, assurance level 1.

Packing shall be accomplished in accordance with table c.Ii for the packing level specified. closure, sealing and reinforcement shall be in accordance with the appropriate shipping container specification.

Items or packages that require packing for acceptance by the carrier shall be packed in exterior type shipping containers in a manner that will ensure safe transportation at the lowest rate to the point of delivery and shall meet, as a minimum, the requirements of the following rules and regulations, as applicable to the mode(s) of transportation to be utilized: (a) postal regulations, (b) department of transportation regulations, (c) civil air regulations, (d) uniform freight classification rules, (e) national motor freight classification rules, (f) american truckers' association rules, (g) other applicable carriers' rules, (h) military air regulations for dangerous materials. consolidation of shipments. all exterior packs of 1.5 cubic feet or less having no single dimension (length, width, height) exceeding 40 inches (and when the total number of such containers in any individual shipment exceeds 25), shall be consolidated, using flat pallets, box pallets, or containers as the consolidating media. dangerous goods shall be prepared for shipment according to applicable department of transportation (dot) regulations and international regulations in effect at time of shipment. shipment by parcel post must comply with postal regulations.

Options can be exercised as to specific method of preservation or dod approved packaging materials to be used. however, basic preservation method shall be retained, supplemental data shall be complied with, and unit package dimensions shall not be increased by more than one inch. equal or better protection shall be given the item and there shall be no increase in the package cost.

No special marking.

Physical protection.

No requirement.

Other Articles Of Iron Or Steel Not Wire Nesoi

Finished Metal Shapes

Articles Of Iron Or Steel, N.e.s.

No special type of cargo code applicable.

Metal hardware.

Construction materials: includes paint and related materials, prefabricated building, wood products, metal and composition mater.

Shipment is not a consolidation and does not exceed 84 inches in any dimension.

Other or no special handling required (sh)

| Code | Definition |

|---|---|

| FN | Factory New. Parts manufactured by the OEM and includes manufacturer certification. |

| NE | New. Parts manufactured by the OEM. May include manufacturer certification or company certification. |

| NS | New Surplus. New material item purchased from excess inventory. |

| OH | Overhauled. Product has been rebuilt and tested in accordance with the manufacturer's specifications by a repair shop (MRO). |

| SV | Serviceable product. |

| AR | As Removed. Product removed from aircraft or platform with no guarentee on the functionality of the part. |

| RP | Repairable. Product can be repaired by a MRO and be given a FAA 8130 or EASA Form 1 certification. |

| Part Number | RNVC | RNAAC | DAC | CAGE |

|---|---|---|---|---|

| 12366465-1 | 2 | ZZ | 2 | 06085 |

| 12366465 | 9 | ZZ | 2 | 06085 |

| 12366465-1 | 2 | ZZ | 5 | 076M6 |

| Name | No. Items | |||

|---|---|---|---|---|

| [You must be logged in to use lists] | ||||