Model or part number: 34000130-7

About this product

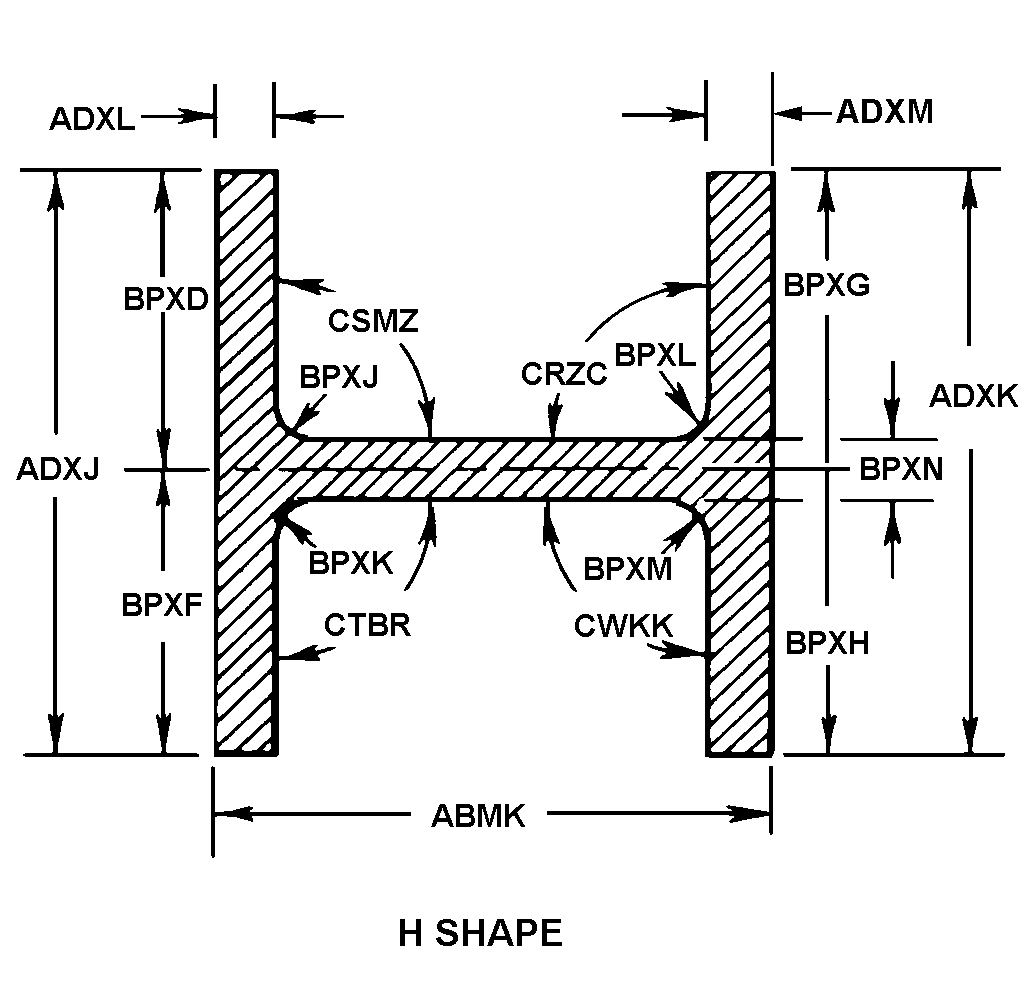

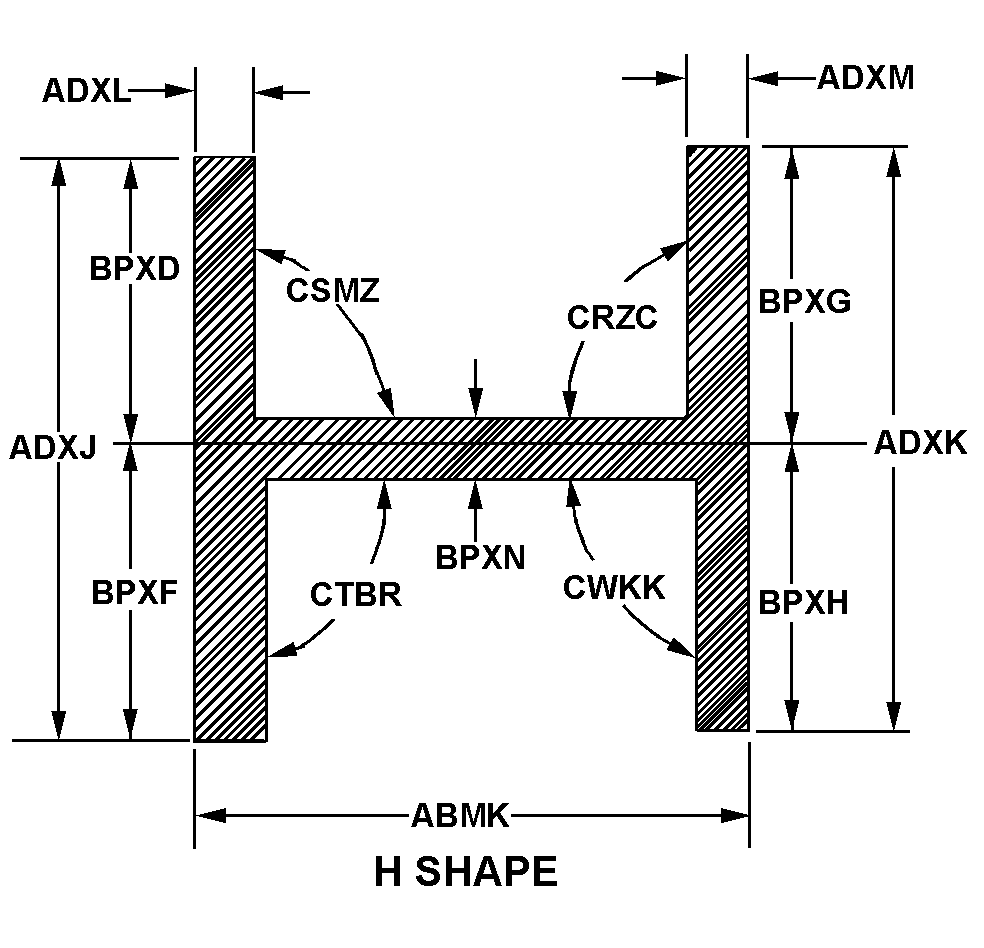

2nd tip offset 0.093 in. Outside; bottom flanges 0.080 in. Thk,13.0667 deg taper tips; tensile strength 22000 psi min,30000 psi max; hardness webster scale 8.0 min,11.0 max; dp matte fin.; fillet radius where bottom left flange joins web flange,0.046 in.; fillet radius where bottom right flange joins web flange,0.046 in.

Wide Flange Beam NSN 9540-01-298-6998.

Factory New, New Material, New Surplus, Overhauled, Serviceable, Repairable, and AS Removed / Used material will be accompanied by a Certificate of Conformance, and any other documents/trace when applicable. We have a 7 year record retention.

We are committed to quality and follow an AS9120 quality management system. AeroBase Group is HAZMAT certified and registered with DDTC,

ITAR, and Aviation Suppliers Association (ASA). All products are 100% inspected.

Quality Commitment »

Delivery of IN-STOCK orders ship same-day when order is placed before 2:00 PM EST.

Delivery dates for NON-STOCK items are estimates based on current backlog and are subject to confirmation at the time of order.

A structural shape fabricated from a ferrous or nonferrous material and resembles the following cross-sectional forms: for the letter h, both flanges of the h section are equal or longer than the width measured along the axis of the web; for the letter i, a 16 2/3 percent slope on the inside face of the ferrous type flange, either one or both of the nonferrous type flanges are shorter than the length measured along the axis of the web; for the letters t and z, on nonferrous type, the web is usually at right angles to the flanges. Letter h section may have a maximum of 5 percent slope on the inside face of the flanges.

No special type of cargo code applicable.

Metal and metal products, nos, (less than 35 feet).

Construction materials: includes paint and related materials, prefabricated building, wood products, metal and composition mater.

Shipment is not a consolidation and does not exceed 84 inches in any dimension.

Other or no special handling required (sh)

| Code | Definition |

|---|---|

| FN | Factory New. Parts manufactured by the OEM and includes manufacturer certification. |

| NE | New. Parts manufactured by the OEM. May include manufacturer certification or company certification. |

| NS | New Surplus. New material item purchased from excess inventory. |

| OH | Overhauled. Product has been rebuilt and tested in accordance with the manufacturer's specifications by a repair shop (MRO). |

| SV | Serviceable product. |

| AR | As Removed. Product removed from aircraft or platform with no guarentee on the functionality of the part. |

| RP | Repairable. Product can be repaired by a MRO and be given a FAA 8130 or EASA Form 1 certification. |

| Part Number | RNVC | RNAAC | DAC | CAGE |

|---|---|---|---|---|

| 34000130-7 | 1 | KZ | A | 24995 |

| Name | No. Items | |||

|---|---|---|---|---|

| [You must be logged in to use lists] | ||||